Messenger Cable Separation Techniques

Instruction Guide

A. Introduction

PCT’s continuing efforts to share technical expertise in last mile drop products will focus this issue on separation techniques of cables and ground wires or messenger wires.

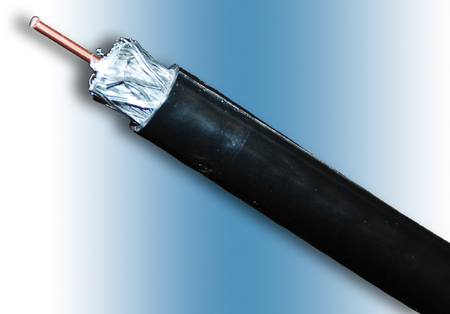

The single most important function of the jacketing on coaxial cable is to protect the integrity of the transmission line from the weather. Exposure to sunlight, wind, temperature extremes and moisture are all factors that coaxial cables face continuously and the jacketing is designed for these environmental events, but carelessness in installation can completely undermine that.

The term messenger cable refers to any cable construction where a coaxial cable is jacketed together with a messenger or ground wire via a small web of jacketing material joining them.

The key to a good installation is always in the preparation of the cable. In messenger cables this is always complicated by the additional jacketing material forming the webbing between the cable and/or grounding / messenger wire. Too much web material on the coax means difficult connector installation which can also compromise the weather sealing ability of the connectors. Too little material on the coax can create a direct path for moisture into the connection.

More importantly, if care is not taken in the separation of the cable and wire, this lack of jacketing at the web can be a

failure point of the jacketing during the installation or after exposure to the environment.

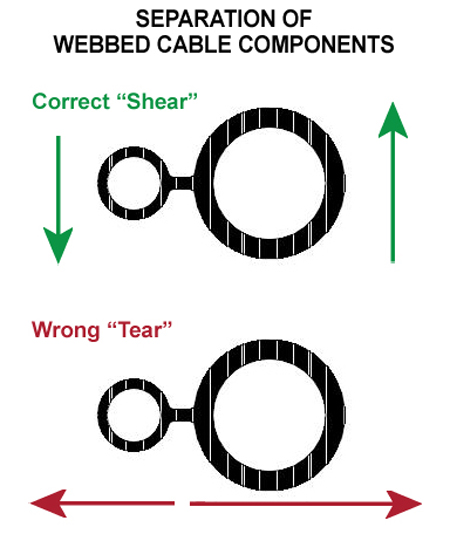

A common mistake made in the process of separation is when the technician tears the cables apart at severe angles in what is termed a “wishbone” pull.

The Society of Cable Telecommunications Engineers (SCTE) has a standard defining the proper method for separating the messenger wire from the coax to prevent compromising the jacketing on both cable and wire, ANSI/SCTE 61 2012. Following this method will ensure coaxial installations a long service life.

Solution to the Problem

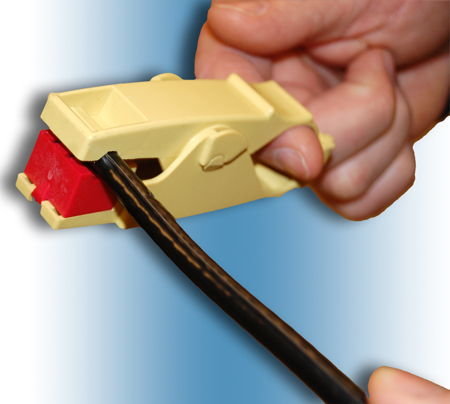

The first step in proper separation of the dual constructed cables begins with using wire or side cutters to cut down the webbing (see Figure 1).

Figure 1

Once the cut has been made in the web, follow the SCTE recommended practice to separate the cables and/or wire (see Figure 2).

Figure 2

Hold the coax vertically in your hand (see Figure 3). Hold the messenger wire in your other hand and pull down vertically following the coax. This method separates the messenger from the cable and minimizes the amount of webbing left on both.

Figure 3

This method of separation reduces stress on the jacketing and allows for easier connector installation.

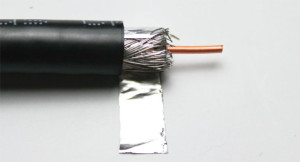

Figure 4 shows the results of a proper separation without damage to the jacketing on either the coax cable or the messenger wire. The minimal webbing material remaining allows for correct coax cable preparation and connector installation.

Figure 4

Prepping the cable is easier with a smaller web profile ensuring tooling does not walk or creep (see Figures 5 and 6).

Figure 5

Figure 6

The finished product with minimal webbing on the jacket means that connector install will be easy in all weather conditions.

The finished cable preparation is clean and ready for connector installation (see Figure 7).

Figure 7

3. For tri-shield cable: Remove the outer layer of foil.

For quad cable: Fold back the first layer of braid wire, remove the outer layer of foil tape and fold back the second layer of braid.

4. To reduce cable insertion force: Evenly flare and separate the braid.

Summary

Following these simple guidelines will reduce risk of damage to the jacketing on coaxial cable and adjoined wire during the installation process. Additionally, the practice of peeling down the messenger means a more balanced webbing residue on each wire allowing for ease of preparation of the cable and improved connector installation.

Remember that the integrity and longevity of the installation begins and ends with proper care of the cable products and how they are prepared for connector installation.