A Billion Loose Connectors Drain Capacity

Like faucets leaking if one faucet was leaking in every home the capacity for water would be limited. The same goes for F Connectors in the home and the data capacity we strive to increase to meet the capacity demand.

Like faucets leaking if one faucet was leaking in every home the capacity for water would be limited. The same goes for F Connectors in the home and the data capacity we strive to increase to meet the capacity demand.

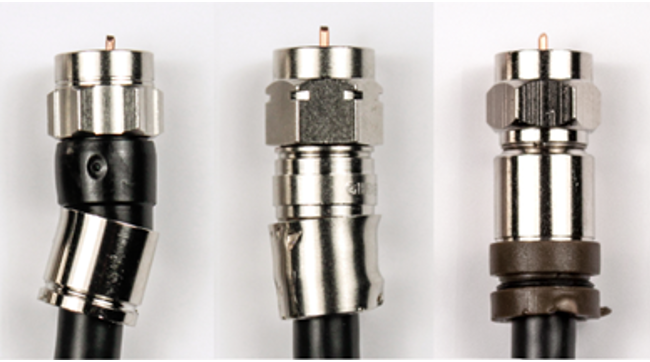

There are billions of connectors out there. From the multi-tap to the ground block to the splitters and amplifier, through wall plates and to the CPE, at least 25 connectors per home are installed. That’s 2.5 billion for 100 million homes. Research has shown that as much as 70% of all indoor connectors may be loose and ~25% of all outdoor connections are loose. Simple fact seen in every home. Signal containment is important as both noise and ingress such as LTE creates noise that will hinder the transfer of data on platforms such as DOCSIS 3.0 and 3.1.

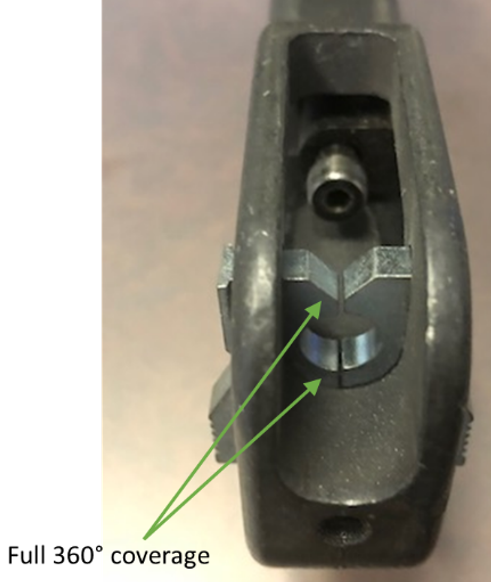

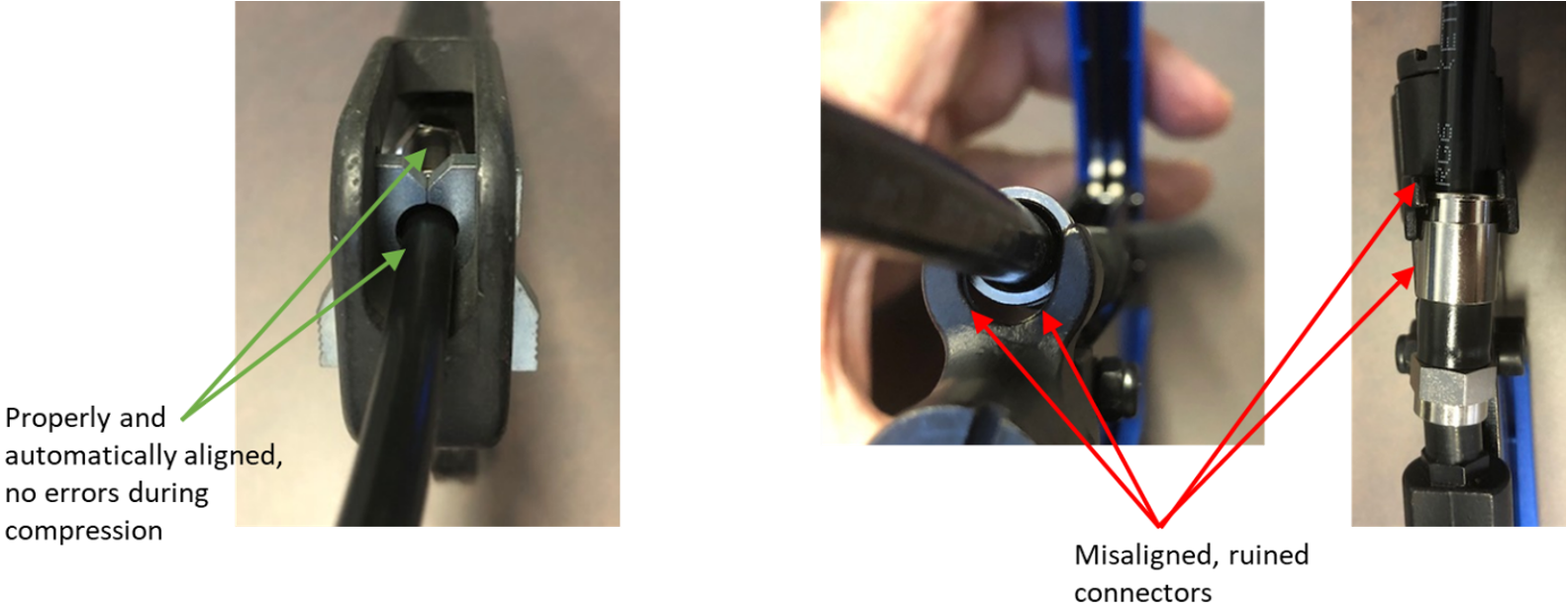

Enter the technology of connections that reduce or limit the noise ingress. A major source of ingress signal degradation is from a situation known as common mode current whereby the loose connections lose continuity to ground. A signal connector in this mode can affect 100’s if not 1,000’s of subscribers from receiving the minimal amount of data capacity.

While connector technology has improved reducing the effects of loose connectors, the simple fact remains that connectors that are loose or become loose still hinder performance. With human craft error and subscriber tampering within the home, a connection that locks or retains retention with electrical continuity to ground eliminates the service call and improves the customer experience for all subscribers. Such a connector exists.