Avoiding Craft Errors with the Best Tools

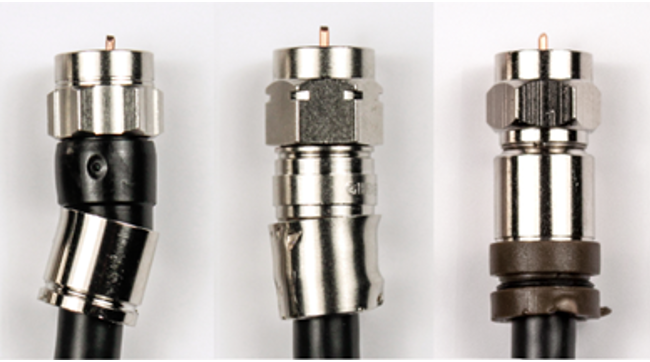

We often take for granted the installation practices with respect to tools. How often have we heard “I make sure all of my connections are tight” but a significant amount are left loose, or are proven to become loose over time. The same goes with drop compression tools that are used to secure connectors to the cable. There are the ones from the DIY store, and some connector manufacturers just cut costs / quality to lower the “free” tool cost burden. But is this serving your customers properly, or costing you more money in service calls?

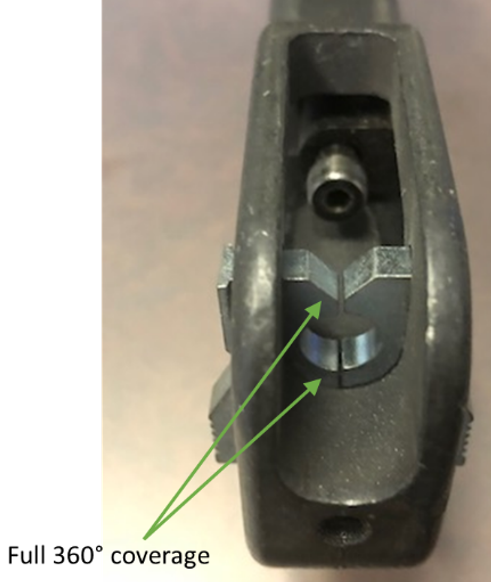

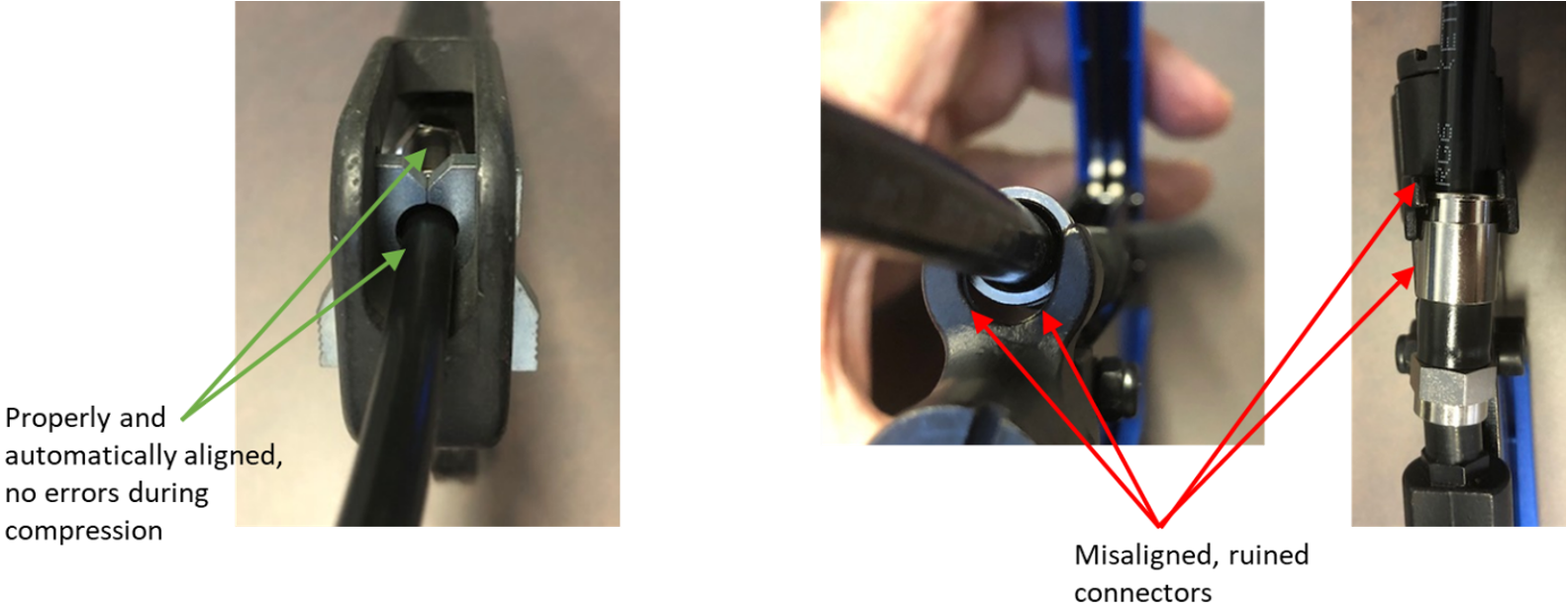

For decades, the industry standard compression tool used by all connector manufacturers was a 360⁰ tool, meaning that it covers the entire back of the compression sleeve as it evenly and uniformly compresses the connector. The 360⁰ tools also capture and align the cable and connector into the correct position so the connector cannot be misaligned during compression. This ensures that the internal components are not jammed or damaged from being compressed at an angle.

The 180⁰ compression tools only cover about one half of the compression sleeve. This allows for misalignment, which can result in distorted outer connector bodies, but can also result in internal damage that may not be visible externally. The misalignment can be both vertically since the cable isn’t captured in the correct compression position, and horizontally as the rotating end wears and no longer locks in place.

So what’s your choice – a good, industry standard tool, or a cheap, partial coverage tool?